Hello, welcome to All-trust WD (Suzhou) Intelligent Technology Co., Ltd. official website!

◆ Convenient, safe and fast

◆ Very quiet operation

◆ High load capacity

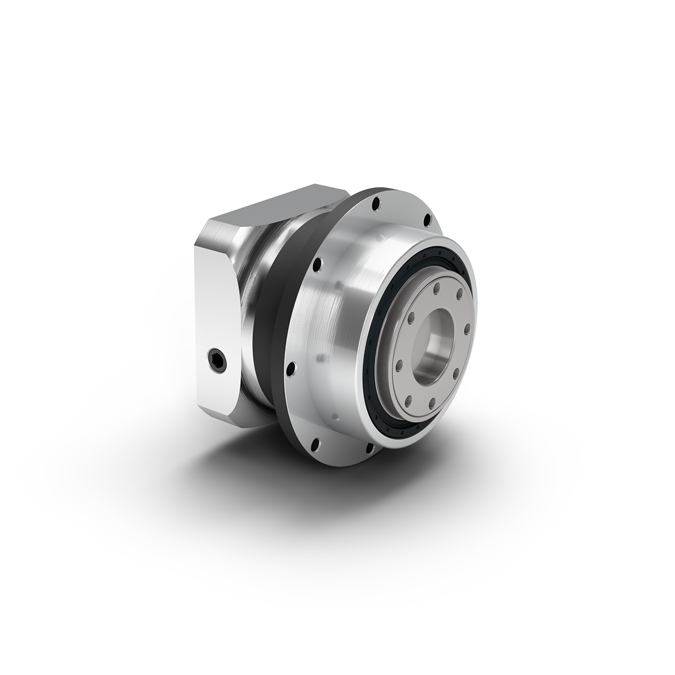

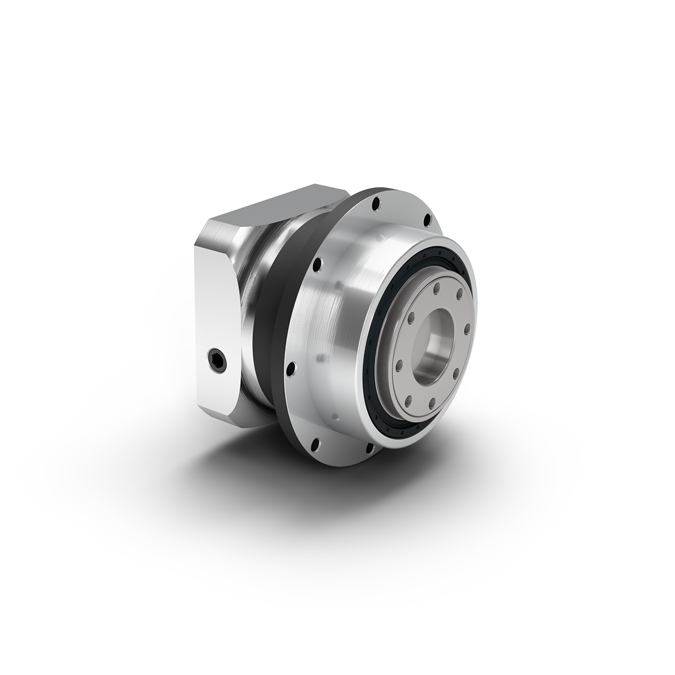

Because of the standardized flange interface, the installation of PSFN is very convenient and safe. The high-precision helical gear developed by us makes other noise reduction measures useless. Due to its high anti tilting torque, this high-precision planetary reducer can complete many difficult tasks.

characteristic

Standardized flange interface

Very quiet operation

High load capacity

Fully sealed

Small and delicate

Inclined gear brings quality improvement

| Reducer parameters | PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | P | |

| transmission ratio | 4,5,7,8,10 | one | |||||

| transmission ratio | 16,20,25,35,40,50,70,100 | two | |||||

| service life |

h |

twenty | |||||

| T2N ×Service life at 0.88 | h | thirty | |||||

| Efficiency at full load | % | 96-97 | |||||

| Minimum operating temperature/maximum operating temperature | ℃ | -25/90 | |||||

| Degree of protection | IP65 |

||||||

| Standard lubrication | Grease (lifetime lubrication) | ||||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||||

| Installation position | arbitrarily | ||||||

| Standard return clearance | arcmin | <3-<5 | |||||

| Reduce return clearance | arcmin | <2 | <1 | <1 | <1 | <1 | |

| Torsional stiffness | Nm/arcmin | 8.2-13.3 | 21.0-31.0 | 55.0-81.0 | 127.0-218.0 | 365.0-668.0 |

|

| Weight of reducer | kg | 1.4-2.1 | 3.0-3.7 | 5.0-6.5 | 11.7-13.8 | 28.5-34.8 | |

| Standard box surface | Box: steel - oxidized after heat treatment (black) |

||||||

| Running noise | dB/(A) | fifty-seven | fifty-eight | sixty-three | sixty-six | sixty-eight | |

| Maximum bending moment based on reducer input flange |

Nm | eighteen | 18/38 | 38/80 | 80/180 | 180/300 | |

Rated output torque

| PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | I | P |

| thirty-nine |

eighty | one hundred and eighty | four hundred and seventy | nine hundred and fifty | four | one |

| forty | eighty | one hundred and seventy-five | four hundred and five | nine hundred and fifty | five | |

| thirty-seven |

seventy-eight | one hundred and seventy-five | three hundred and fifty-five | nine hundred | seven | |

| thirty-nine |

seventy-five |

one hundred and fifty-five |

three hundred and fifty |

- | eight | |

| twenty-eight | fifty-nine |

one hundred and forty | three hundred and five | seven hundred and fifty | ten |

|

| thirty-nine | eighty | one hundred and eighty | four hundred and fifty | nine hundred and fifty | sixteen | two |

| thirty-nine | eighty | one hundred and eighty | four hundred and fifty | nine hundred and fifty | twenty | |

| forty | eighty | one hundred and seventy-five | four hundred and five | nine hundred and fifty | twenty-five | |

| forty | eighty | one hundred and seventy-five | four hundred and five | nine hundred and fifty | thirty-five | |

| thirty-nine | eighty | one hundred and eighty | four hundred and seventy | nine hundred and fifty | forty | |

| forty | eighty | one hundred and seventy-five | four hundred and five | nine hundred and fifty | fifty | |

| thirty-seven | seventy-eight | one hundred and seventy-five | three hundred and fifty-five | nine hundred | seventy | |

| twenty-eight | fifty-nine | one hundred and forty | three hundred and five | seven hundred and fifty | one hundred |

Output shaft load

| PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | |

| Radial force of 20000h | two thousand one hundred and fifty | three thousand nine hundred and fifty | four thousand and nine hundred | twelve thousand | twenty-three thousand |

| Axial force of 20000h | four thousand and three hundred | eight thousand and two hundred | nine thousand and five hundred | eight thousand and five hundred | sixteen thousand |

| Radial force of 30000h | one thousand and nine hundred | three thousand and five hundred | four thousand three hundred and fifty | eleven thousand | twenty-one thousand |

| Axial force of 30000h | three thousand and eight hundred | seven thousand and two hundred | eight thousand and four hundred | seven thousand and five hundred | fourteen thousand |

| 20000 h tilting moment | one hundred and thirty-two | three hundred and twenty-six | four hundred and seventy-five | one thousand and thirty | two thousand four hundred and forty-five |

| 30000h inclination moment | one hundred and seventeen | two hundred and eighty-nine | four hundred and twenty-two | nine hundred and forty-four | two thousand two hundred and thirty-two |

Geometric dimensions

| PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | P | |

| Pitch circle diameter of mounting hole at output end | thirty-one point five | fifty | sixty-three | eighty | one hundred and twenty-five | |

| Output flange retaining boss diameter | sixty-four | ninety | one hundred and ten | one hundred and forty | two hundred | |

| Diameter of output flange | eighty-six | one hundred and eighteen | one hundred and forty-five | one hundred and seventy-nine | two hundred and forty-seven | |

| Total length | seventy-one | eighty-nine point five | one hundred and eight | one hundred and forty-two | one hundred and seventy-two | one |

| ninety-nine point five | one hundred and eleven point five | one hundred and thirty | one hundred and seventy-three | two hundred and seventeen | two | |

| Length of output flange | nineteen point five |

thirty | twenty-nine | thirty-eight | fifty |

Copyright © All rights reserved by Zhongxin Weichuang (Suzhou) Intelligent Technology Co., LtdSUICPB No. 19054578